Best Conveyor roller supply for Malaysia

Best Conveyor roller supply for Malaysia

Conveyor Roller One Stop Solution

— Rollflex ( M ) Sdn Bhd –

Conveyor Roller type :

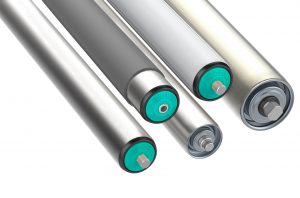

Gravity conveyor roller

Gravity conveyors roller are the most popular and simple method of conveying goods. This type of conveyor rollers are non-powered. Goods are moved and conveyed by gravity or human force. It is usually arranged horizontally or declined.

Horizontal Arrangement:

The goods are moved by human force. Suitable for the conveying of light weight products, short distances and infrequent work.

Declined Arrangement:

The goods are conveyed in the decline direction by gravity force. Increasing the weight of the goods and the angle of the decline increases the speed of the goods.

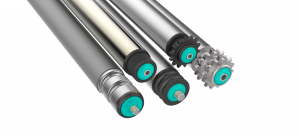

Conveyor roller – Driven type

Driven conveyor roller

Driven conveyor roller conveying transports goods steadily, reliably and with accurate speed. According to the driving method, it may be classified as “belt driven conveying” ( Polyvee conveyor roller or “chian driven conveying” ( Sprocket conveyor roller ).

Belt driven:

Reliable, low noise, low environmental pollution, able to run at high speed. Oily working conditions should be avoided. – Polyvee belt conveyor roller.

Chain driven:

High load capacity. Suitable for a wide range of working environments including oil, water and high temperature however the chain is easily worn in a dusty environment. The conveying speed should not exceed 30m/min. – Sprocket conveyor roller.

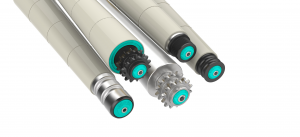

Conveyor roller – Accumulating type

Accumulating conveyor roller

Accumulation driven conveyor roller are use in accumulation conveyors not only achieve the function of common drive conveyors but also allows goods to stop and accumulate on the conveyor line without stopping the conveyor drive and without any obvious increase to the driving resistance.

In normal conveying the accumulation device transmits the driving force. When goods stop and accumulate, the operating moment of resistance exceeds the definitive driving force. The accumulation friction sleeve slips allowing the goods to stop the roller whilst the conveyor drive is still running.

Curve conveyor roller

The different diameters over the length the tapered roller i.e. small one end and large the other end, provides a linear velocity to ensure smooth conveying of goods around the curve.